Our Technology

ROVAR - Our subsea 'Forklift'

Smarter Subsea Handling have produced this animation illustrating 'ROVAR' - our concept for a subsea 'forklift' buoyancy module incorporating our VBS. This You Tube video illustrates the buoyancy system being overboarded in a similar way to a Remotely Operated Vehicle. As it enters the water the dump valves are opened allowing water to fill the buoyancy caissons and with slightly negative buoyancy in water the system sinks slowly to the seabed.

Under the combined control of thrusters and buoyancy trimming the system locates its target load, attaches to the load and then by closing the dump valves and generating gaseous nitrogen from its liquid nitrogen source, water is discharged from the buoyancy chambers and the system and its load becomes buoyant.

The controls allow the system to 'hover' at a specified depth, in this case just a few metres above the seabed. Using its vectored thrusters the system can then be driven to its required location to despatch its load. The load is lowered to the seabed by slightly venting the buoyancy chambers of gas. Once the load has been safely detached, the system can return to pick up another load. Slight variations in buoyancy can be controlled from the surface to optimise its 'flight' through the water.

Variable Buoyancy System

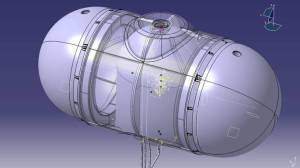

The Variable Buoyancy System comprises a load-bearing advanced composite buoyancy chamber and integrated liquefied gas storage 'dewar'.

Gas is vaporised from its cryogenic state in a controlled manner to generate precisely controlled levels of buoyancy for use in marine lifting and lowering operations.

The system is currently designed to operate down to 1000 msw with plans to extend that to 2000 msw and beyond with alternate cryogens.

Product development

ROVAR is a fully scalable technology and can be adapted to address different lifting and handling challenges subsea. Our standard unitary systems are ROVAR-01 and ROVAR-20 which can also be deployed in multiplex modes for manoeuvring of much heavier or more complex loads requiring multiple lifting points due to shape, uneven load distribution etc.

ROVAR-01 has a 1-Tonne lift capability and can be used for debris and UXO removal from restricted areas. It has a footprint of approximately 2.7m length and 1.1m cross-section.

ROVAR-20 has a 20-Tonne lift capability and can be used for more substantial offshore handling and recovery as an underwater crane or 'seabed forklift'. It has a footprint of between 4m and 6.6m long with a cross-section of 2.7m.

Multi-functional Lifting and Handling Systems for Subsea Infrastructure Construction Support and Removal

Smarter Subsea, Standard Lifting Handlin[...]

Adobe Acrobat document [2.2 MB]

In the context of specific customer challenges, we have now developed two new product designs to aid with the removal of pipeline bundles and remediation of seabed habitats in the oil and gas sector, and the handling of cables, pipelines and umbilicals during installation and IRM across multiple underwater sectors .

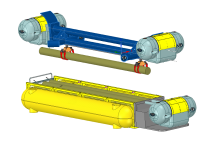

Adapted subsea 'wet baskets' with integral buoyancy caissons (ROVAR-WB) are deployed as ‘seabed trailers’ and then moved laterally to the required seabed position by a master ROVAR unit. They are suitable for wet lay-down in multiple scenarios for hub and spoke operations. The ROVAR master unit acts as a ‘subsea truck’ in shunt or tow modes.

The ROVAR Buoyancy Beam (ROVAR-BB) is deployed to handle and spread the load of long structures such as pipeline bundles, cables, umbilicals and tubulars. These can be recovered to, or deployed from, our subsea baskets, which in turn can be connected to ROVAR ‘trucks’.

Buoyancy is generated in both structures which are then raised to the surface for recovery to semi-submersible barge or by back-deck crane.

Smarter Subsea Handling has developed two specific pipeline bundles recovery solutions utilising ROVAR-BB and ROVAR-WB:

- Cutting into c.20m lengths and placing into ROVAR-WBs (wet baskets) for transfer to barge, or

- Cutting into lengths of c.100m by ROVAR-BBs for chained tug tow to coastal recycle ports.

LIFTING AND HANDLING SOLUTIONS FOR PIPELINE BUNDLES AND CABLING

Smarter Subsea Solutions for Pipeline Bu[...]

Adobe Acrobat document [2.7 MB]

Value proposition

Our primary value propositions for our variable buoyancy solutions and the ROVAR range of solutions, irrespective of markets, and relative to other lifting and buoyancy technologies are:

- Cost reduction per lifted tonne

- Reduced support vessel and ancillary equipment requirements

- Reduced energy consumption and carbon emissions

- Amortisation (underlying Capex)

- Extended weather and sea state window for operations

- Lightweight

- Surface handling and safety

- Minimal overhead to recover own weight

- Load bearing capacity to weight ratio

- Versatility

- Fully scalable

- Scope for lateral 'carry' as well as vertical 'lift'

- Accessibility to restricted locations

- Suitable for a range of tasks across Life of Field activity